The ventilation control method was written in FORTRAN IV, the computer language of the time, and installed in an electronic computer (MELCOM 350-30F II), the central control unit. The central control unit was installed at the Iida Central Control Station attached to the Iida Interchange, about 12 km from the Enasan Tunnel. All measurement data of traffic volume meter, CO meter and VI meter, which are necessary data for ventilation operation of the Enasan Tunnel 4 ventilation station, are sent from the transmission equipment (remote control station) to the transmission equipment (remote control master station) of the Iida Central Control Station.

The central controller receives measurement data from the transmission equipment (remote control master station), and with these measurement data as input, calculates the ventilation volume every 10 minutes. The calculation result is output to a transmission device (remote control master station), and is returned to the ventilation control board via the transmission device (remote control station) of each ventilation station. The ventilation control panel would drive the ventilation fan based on the received ventilation volume.

VCP: Ventilation control panel RCS: Remote control station RCMS: Remote control master station

CCU: Central control Unit

In addition to the four ventilation stations in the Enasan Tunnel, the central control unit in the Iida Central Control Station collects data from two ventilation stations in the Amikake Tunnel, two power receiving stations in the Enasan Tunnel, four interchanges in Iida and elsewhere, three SA/PAs, and two weather stations, and gives necessary orders to all facilities based on these data. In this way, the equipment handled by this central control unit covers almost everything related to highway operation, including ventilation, power reception and transformation, private power generation, lighting, disaster prevention, signage, mid-wave loudspeaker mobile radio, weather, traffic flow detection, etc.

Such a system consisting of a central control unit (industrial computer) and transmission equipment was called a (remote) centralized supervisory and control system, and was widely adopted in the power, industrial and public sectors in 1975, when industrial computers were expensive.

The Mitsubishi Electric Technical Bulletin, published in December 1975, was edited to coincide with the completion of the Enasan Tunnel as a special issue on electrical products for road tunnels. This shows that Mitsubishi Electric manufactured and constructed the electrical equipment ((1) power supply equipment, (2) motors and control systems for ventilation equipment, (3) central control system, (4) remote monitoring and control equipment, and (5) monitoring equipment) for the Enasan tunnel.1)

According to the Enasan Tunnel Construction Journal, the first construction work, the “Enasan Tunnel Iida-bata Trial Drill Shaft Test Work” began in April 1967. After that, the civil engineering work proceeded with the construction of the auxiliary tunnel and the main tunnel from the Iida side and Nakatsugawa side, the Iida side inclined shaft, and the Nakatsugawa side shaft, respectively. On the other hand, the construction work began in May 1969 with the “Iida direction special high-voltage substation new installation for Enasan Tunnel construction,” and by 1973, orders for power receiving and transforming work, tunnel lighting work, disaster prevention equipment work, and remote monitoring and control equipment were being placed one after another.

In terms of the number of construction projects, civil engineering and construction projects numbered 54 and facility construction projects 23. Of these, Mitsubishi Electric received orders for three facilities. This shows the grand scale of the construction.

I was responsible for the development of ventilation control programs, which is just one component (part) in a single subsystem. Working as part of the project gave me first-hand experience of the wide range and field of people that must be involved in completing of project. Through my work, I also deepened my understanding of internal organization (Business, Manufacturing and research laboratories). Interaction with the people who support the organization became the starting point for building internal network.

Enasan Tunnel opened on August 23, 1975. In the preface to the Enasan Tunnel construction journal, Kazuo Hirano, then head of the Nagoya Construction Bureau of the Japan Highway Public Corporation, wrote about the opening of the tunnel as follows:

「It was on August 23, 1975, that the Enasan Tunnel, which penetrated the Central Alps and directly connected the Kiso and Ina valleys for the first time, was spectacularly opened to traffic with the hopes and expectations of the local people that a “Second dawn was coming. At that time, it was reported that a typhoon was approaching, and the wind and rain that had begun the night before had become even more intense in the morning, reaching its climax by the time the ribbon cutting was held. The opening ceremony was truly held in the midst of great turmoil, but as I watched, I felt in my heart that this was indeed the right way to end the eight-year struggle to overcome the unprecedented evil geology and end the battle between mud and water.」2)

I heard this news at the central research center in Amagasaki and was relieved to hear that I had been able to live up to the trust of the customer.

The following song by Mitsuyoshi Maeda, then president of the Japan Highway Public Corporation, was inscribed on the memorial for the opening of the Enasan tunnel at Achi PA.

「Kaminomisaka ka shikomi ugachi Ena no yama ni atarashiki yo no michi tōri tari」

Meaning: “The way of the New World passes through the Enasan where the gods are wandering”.

After opening, ventilation control worked smoothly. As the person in charge of ventilation control, I visited Iida Central Control Station several times to check the situation. The section chief in charge remained at the central control station for several more months and kept a flower pot in his room. When I visited with Professor Yuichi Nishikawa, who was leading my research at the time, I had fond memories of being guided in detail by the section chief in charge.

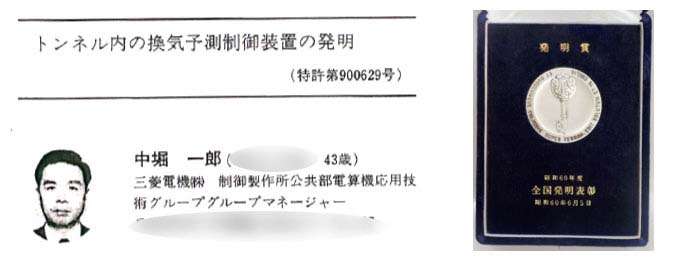

In 1985, 10 years after the tunnel was opened, the tunnel ventilation system developed in the Enasan tunnel, “Invention of a Ventilation Predictive Control Device in the Tunnel,” was selected for the National Invention Award.

The five co-inventors of this patent were all invited, together with their spouses, to the award ceremony held at the Tokyo Prince Hotel on June 5th of the same year. At the award ceremony held in the Magnolia Room on the 2nd floor of the same hotel, we received message from His Highness Prince Hitachi, the President of the Inventors’ Association. Prime Minister Yasuhiro Nakasone, Mr. Dai Ibuka, President of the Inventors’ Association, and Mr. Eiji Toyoda, Vice President, were in attendance. We owe this award to the guidance of everyone who was involved in the work on the Enasan Tunnel, and we deeply appreciate their fortunate support.

(Mt. Enasan tunnel ventilation control system completed, continued on next theme)

References:

1) Mitsubishi Electric Technical Journal, Special Feature on Electrical Equipment for Road Tunnels, December 1975

2)Japan Road Public Corporation, Nagoya Construction Bureau, Enasan Tunnel Construction Journal, July 1977.