Application of thyristor motors for Blower and Exhaust Fans

In 1958, 17 years before the Enasan Tunnel was opened, the Kanmon Tunnel(3461m), Japan’s first tunnel with a full-scale transverse ventilation system, was opened to traffic. According to the technical history of expressways, the Kanmon Tunnel was the first in the world to use a variable rotor blade type axial flow fan for an air supply and exhaust system1).A pole-number conversion induction motor capable of switching between high speed and low speed was used as the motor for driving the blower fan and exhaust fan. Later, the Tennozan Tunnel on the Meishin Expressway (opened in 1963) has continued to use a system that combines a variable blade-type axial fan developed in the Kanmon Tunnel with a polarity conversion induction motor2).

On the other hand, the Enayama Tunnel adopted a system in which the fixed-wing axial fan was driven by a continuously variable speed thyristor motor (cycloconverter + synchronous motor), the latest technology of the time, instead of the conventional variable-wing type.

The Enasan Tunneling Journal presents a functional and economic comparison of thyristor and pole number conversion motors3). Functional comparisons shows that thyristor motors are more effective in terms of controllability and efficiency, while economic comparisons show that the total cost of two substations and four ventilation stations shows little difference between thyristor motors and pole number conversions motors, with a difference of 0.4%. The adoption of the thyristor motor was probably a comprehensive decision based on these functional comparisons and economic comparisons.

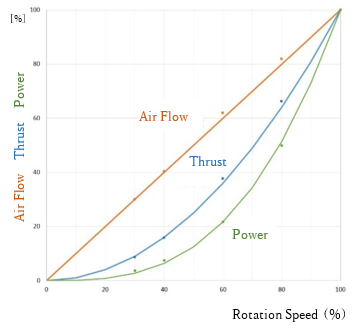

The specifications of the ventilator in the Enayama tunnel and the air flow, discharge dynamic pressure, and power characteristics during the speed control are shown in the table and figure below. This figure confirms the characteristic of the axial fan in that the airflow, thrust and power are proportional to the first, second and third powers of the number of revolutions, respectively.

| Ventilation room | Total exhaust |

Bore (mmφ) |

Steps | Flow Q(㎥/s) |

Pressure H(mmAq) |

Rotation N(rpm) |

Output (kW) |

Units |

|

Inclined Shaft |

Blower | 2800 | 2 | 160 | 495 | 700 or less | 1215 | 2 |

|

Exhaust |

2800 | 2 | 160 | 473 | 700 or less | 1155 | 2 | |

| East portal | Blower | 2800 | 1 | 160.5 | 349 | 750 or less | 855 | 2 |

| Exhaust | 2800 | 1 | 160.5 | 324 | 750 or less | 795 | 2 |

Enasan tunnel ventilation specifications4)

In the Enasan Tunnel, the substations at the two entrances receive special high-voltage 77 kV power, and after the 77 kV is stepped down to 22 kV using the main transformer, line distribution was adopted at 22 kV using power cables laid in the auxiliary shafts dug in parallel with the tunnel. There are four ventilation stations, located at both portals, underground in the shafts and underground in the slanting tunnels. At each ventilation station, power was received from a 22kV cable, and 580V was supplied to the thyristor motor, which is the ventilation equipment, through a step-down transformer.

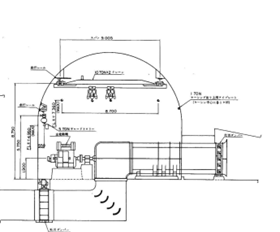

A photo and installation diagram of the thyristor motor and exhaust system installed in the underground ventilation station are shown below.

The thyristor motor used in the Enayama tunnel was the first of its kind in the world for ventilation in road tunnels. It should be noted that the control semiconductor thyristor (SCR) of the time (1975) has since been completely replaced by the power transistor (IGBT). In line with this, cycloconverters using thyristors have almost disappeared from variable frequency power supplies for AC motors and have been almost completely replaced by PWM (pulse width modulation) inverters using power transistors (IGBTs). In recent years, these PWM inverters have become widely used in tunnel blowers and exhaust fans. The thyristor motors in the Enasan Tunnel mark the origins of this trend and are of great historical significance. (Continue)

Reference:

1) Technical History of Expressway Facilities, December 2022, Japan Expressway Research Association, p. 326.

2) Technical History of Expressway Facilities, December 2049, Japan Expressway Research Institute, p 336.

3) Enasan Tunnel Construction Journal, July 1977, Nagoya Construction Bureau, Japan Highway Public Corporation, p714, p716.

4) Enasan Tunnel Construction Journal, July 1977, Nagoya Construction Bureau, Japan Highway Public Corporation P696

5) Enasan Tunnel Construction Journal, July 1977, Nagoya Construction Bureau, Japan Highway Public Corporation P682

6) Enasan Tunnel Construction Journal, July 1977, Nagoya Construction Bureau, Japan Highway Public Corporation P685

7) Enasan Tunnel Construction Journal, July 1977, Nagoya Construction Bureau, Japan Highway Public Corporation P677