People from various technical fields, such as civil engineering, architecture, and equipment (Mechanical, Electrical, System Control) are involved in long tunnel construction. The basic policy was summarized in basic design and plan. Especially, the basic design plan for ventilation method is the most important things related to civil engineering, and facilities.

The Enasan tunnel( Primarily)is a one-tube, two-lane, two-way tunnel with an acceptable limit concentration of 100~150PPM of CO and limit of transmittance of 40% of Soot(VI).

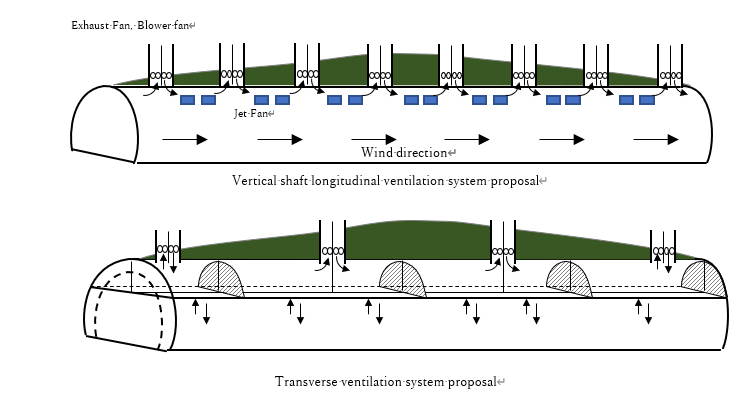

At the study stages, six ventilation systems including, longitudinal, transverse, semi-transverse, were compared. Among them, the vertical shaft longitudinal and transverse flow types were judged to be most applicable to tunnels over 8000m.

Comparison of shaft longitudinal and transverse ventilation system

| Shaft longitudinal System | Transverse ventilation System | ||

|

Cost |

Area | Small cross-section area as no duct required | Large cross section required for ventilation ducts |

| Shaft | 8 | 4 | |

|

Performance |

Reliability |

Small | High |

| Safety | Disaster prevention system requires consideration | Disaster prevention system is simple |

In addition to the two tunnel entrances, vertical shaft and inclined shaft were provided as ventilations ducts for installing blowers and exhaust fans required for transverse ventilation system.

The length and slope of shaft will be 620m and 1420m, respectively, and the capacities(kW) of the blowers and exhaust fans for each will be shown as below:

Enasan Tunnel Blower and Exhaust Fan Capacity

| West portal | UndergroundShaft | InclinedShaft | East portal | |

| Exhaust Fan | 2×485kW | 2×1025 kW | 2×1155 kW | 2×795 kW |

| Blower | 2×345 kW | 2×990 kW | 2×1215 kW | 2×855 kW |

It must be taken into account that vehicle emissions (CO,Soot) were greater than they are today, but it is surprising that gross ventilation power capacity was exceeded 10,000kW , reaching 13,730kW.

(Continue)

References:

[1] Enasan Tunneling Journal page 673 “Part 3: Management Facilities and Systems Chapter 1: Management Facilities 1. Ventilation Facilities”

[2] (Public)Express Highway Research Institute History of Highway Facilities TechnologyP-341,” Tunnel ventilation of central Expressway Enasan Tunnel

[3] Mitsubishi Electric Technical Report Vol. 49, No. 12, P767 “Special feature on electric motors for road tunnels”, December 1975 “Electric motors and control systems for highway tunnel ventilation equipment”.